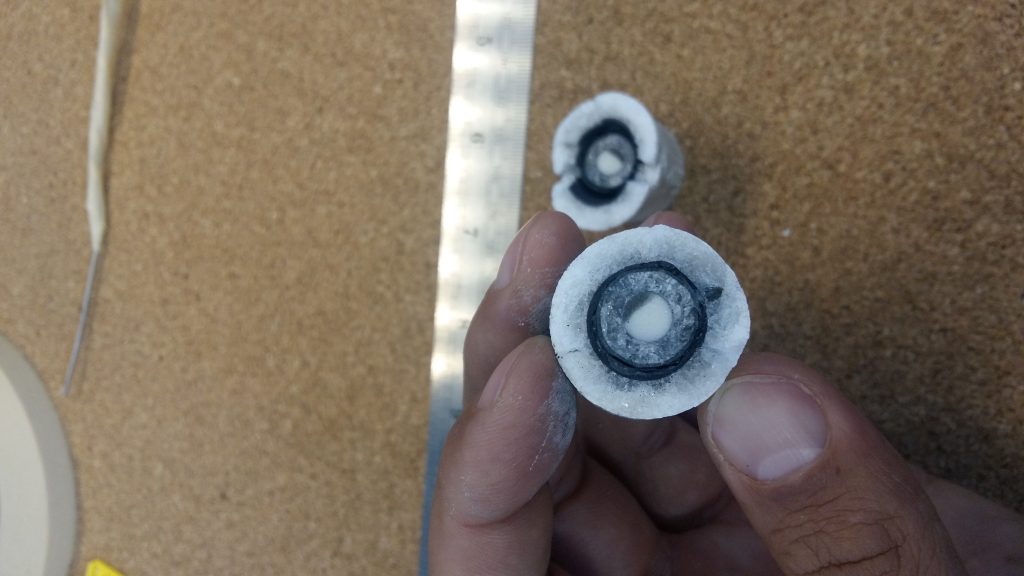

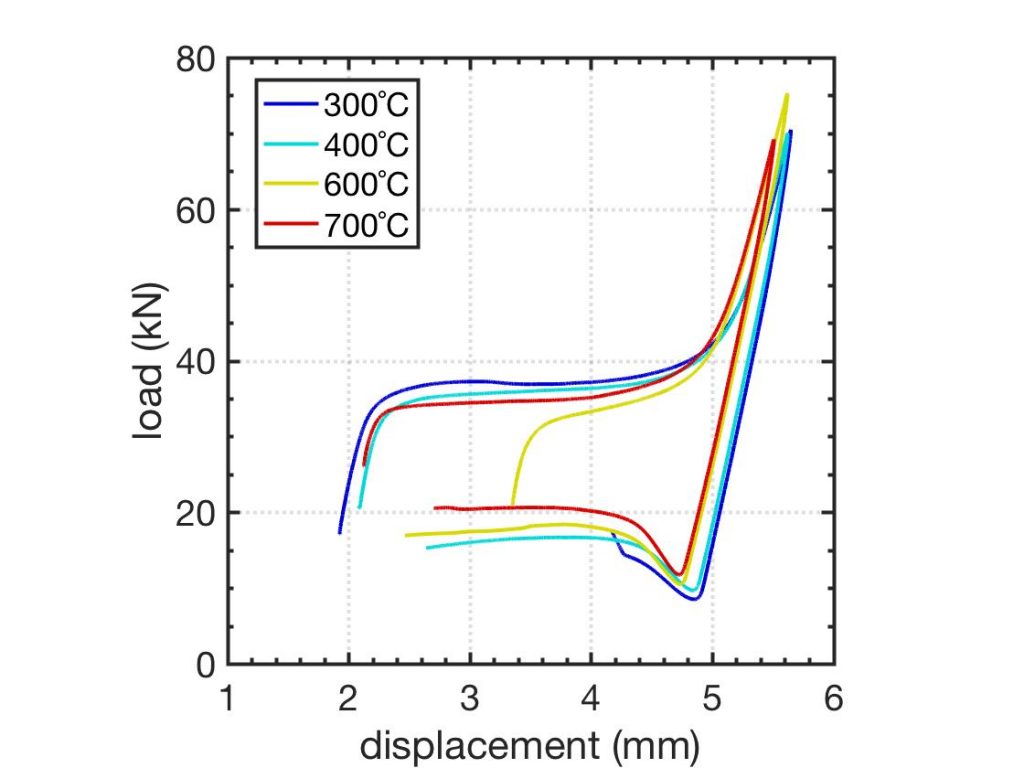

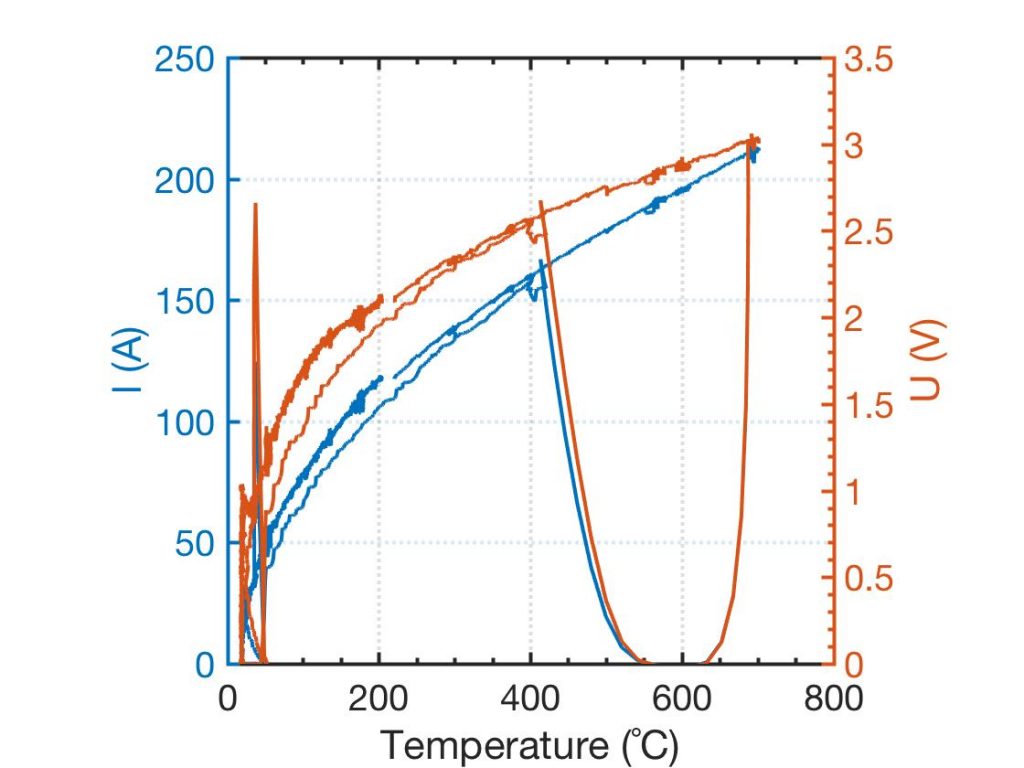

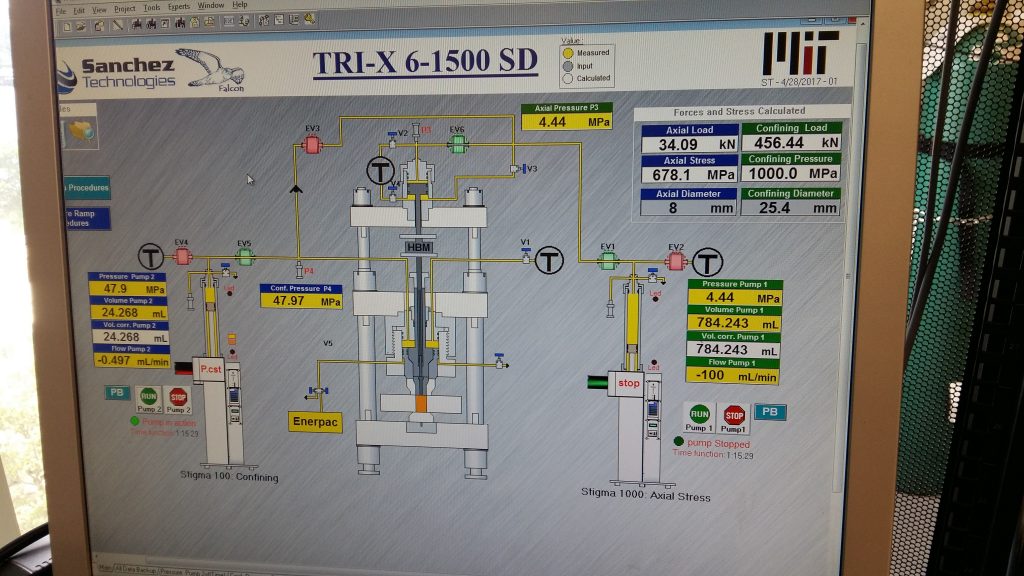

We just finished a very successful 3 day long heating and rig stiffness test. The results were very consistent and show a loading stiffness of ~15 µm / kN at a range of temperatures (300˚C to 700˚C) at 0.6 GPa confining pressure. Since we currently operate only with one pressure vessel, we stay in the lower limits of the P-T space we can achieve to prevent pressure vessel failure and delays to our tests. Our main aim is to reach about 2 GPa confining pressure and 1150˚C – this will allow us to deform partially molten mantle rocks with a simple NaCl pressure medium.